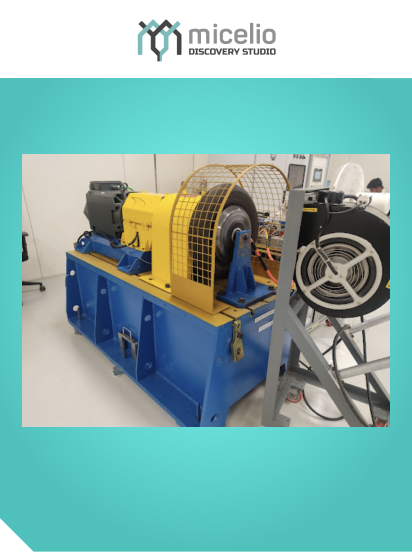

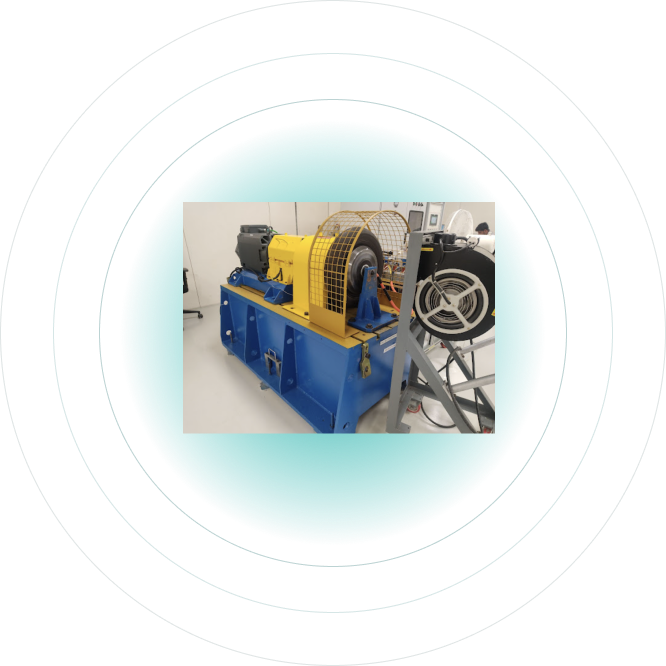

Motor Test Bench

Our Motor Test Bench is meticulously designed to bridge the gap between R&D and large-scale production. Experience a seamless transition from prototype to production with our state-of-the-art Motor Test Bench. It ensures precision and consistency, accelerating your journey from concept to market-ready products.

Equipped with data acquisition systems and a diverse range of testing capabilities, our solutions empower you to gain in-depth insights into torque, speed, efficiency, and other crucial parameters across various operating conditions.

Motor Test Benches are equipped with various instruments and sensors to measure parameters such as torque, speed, power

consumption, efficiency, vibration, and thermal characteristics. This allows for comprehensive testing and analysis of motor performance under different load conditions and operational scenarios.

You can implement quality control measures at an affordable rate with Motor Test Benches as its benefits are substantial in battery and motor optimisation. Our Motor Test Benches provide a reliable and cost-effective way to ensure consistent performance across your entire motor product range. Investing in motor testing is an investment in your future of EV product development.

Current Challenges in the Ecosystem

The Electric Vehicle (EV) industry faces challenges in optimizing motor efficiency for longer range, reducing motor size and weight, improving thermal management for high power densities, and lowering production costs while ensuring reliability. Motor efficiency directly affects battery design, as more efficient motors can reduce battery size and weight.

Power Density and Range

Thermal Management for Motor Heat Generated

Battery Dependence on Motor Efficiency

Rare Earth Element Reliance

Standardization for Motor Interfaces and Communication Protocols

Noise Concerns for High-Frequency Noises

How Can Motor Test Benches Solve the Above Challenges?

Motor testing is a critical component of the electric vehicle revolution. By rigorously testing electric motors, engineers can optimize performance, efficiency, and durability. This rigorous testing process enables the development of high-performance, energy-efficient motors that extend vehicle range and reduce charging frequency. Additionally, it aids in developing smaller, lighter, and more cost-effective motors while exploring sustainable alternatives to rare earth materials. These advancements drive innovation, sustainability, and efficiency in electric mobility.

Provides Valuable Data To Accelerate Motor Design And Refinement

Assists in Faster

Troubleshooting

Enables Failure Analysis and Root Cause Analysis

Accelerates Development of Reliable and Futuristic Vehicles

Features of Our Motor Test Bench

The Motor Test Bench provides a controlled environment to assess performance, durability, and thermal evaluation of a motor. It helps in various key validation during R&D and testing phase as listed below:

Performance Validation

Durability Testing

Thermal Management Evaluation

Calibration and Control System Optimization

Performance

Validation

Durability

Testing

Thermal Management

Evaluation

Calibration and Control

System Optimization

Performance

Validation

Durability

Testing

Thermal Management

Evaluation

Calibration and Control

System Optimization

Motor Test Bench Technical Specifications

|

Motor Test Bench

|

|

|

Rated Power

|

36 KW

|

|

Rated Torque

|

172 Nm

|

|

Max Speed

|

6500 rpm

|

FAQs

Our Motor Test Bench is capable of testing a wide range of motors, including AC motors such as induction motors, synchronous motors, servo motors, and stepper motors; DC motors like brushed DC motors, brushless DC motors (BLDC), and series and shunt wound DC motors. Additionally linear motors and universal motors, as well as Electric Vehicle (EV) motors like Permanent Magnet Synchronous Motors (PMSM) and induction motors for EVs, can also be tested.

To mount a motor on a Motor Test Bench, various fixtures are needed to ensure secure and precise positioning. These include adjustable motor mounting brackets and solid base plates for stable foundation, as well as couplings and adapters to connect the motor shaft to the load or measurement devices.

The price is decided on a project basis after understanding your testing requirements and overall validation objectives. To know more, please get in touch with us at [email protected].