Hardware-In-Loop Testing

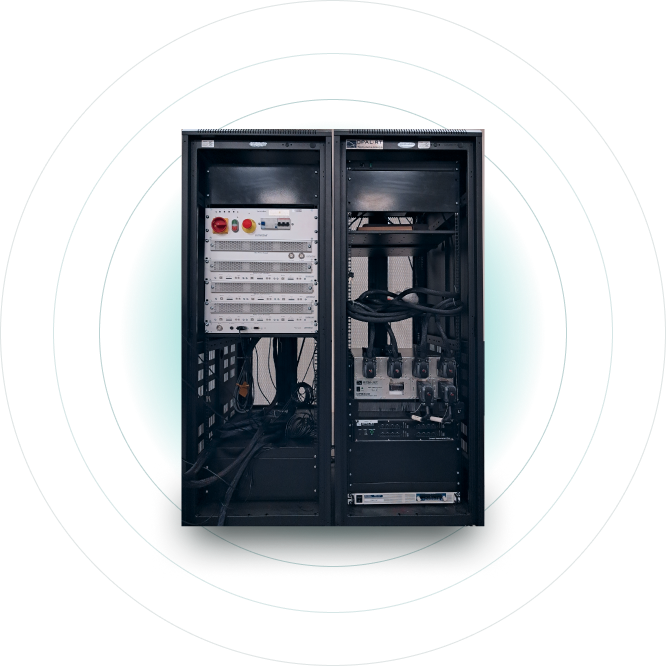

With our Hardware-in-Loop (HIL) system, you are not just getting a tool; you are getting a partner in your journey of product validation. Our HIL farm facility has capabilities to handle complete e-powertrain architecture and validate its control software.

The Digital Twin Facility, a joint initiative of Micelio and Automotive Research Association of India (ARAI), brings you ‘Hardware-in-Loop’ testing that emulates real world conditions with multiple scenarios and test cases.

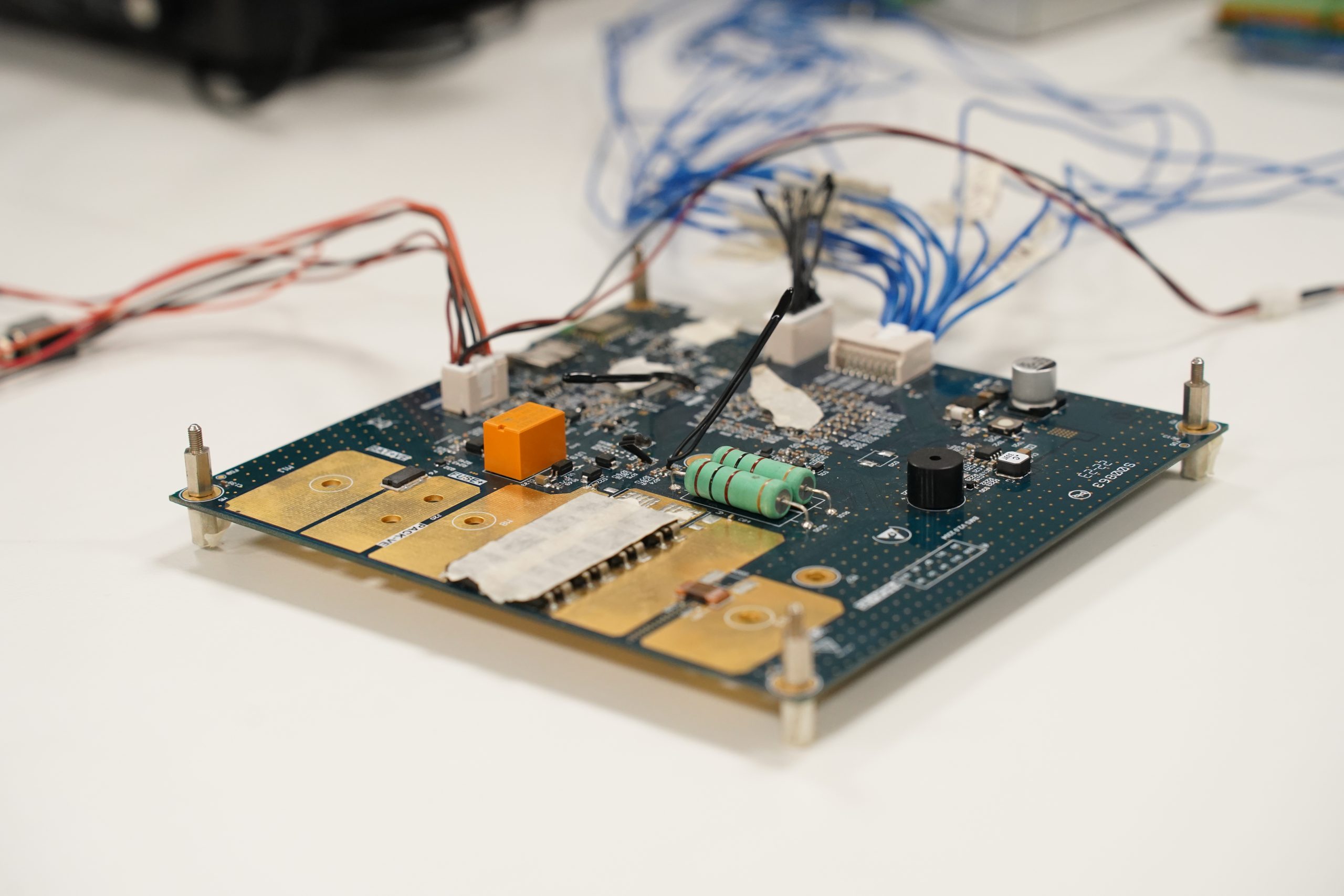

Hardware-in-Loop (HIL) testing system provides a comprehensive analysis of Electronic Control Units (ECUs) including but not limited to Motor Control Units (MCUs), Vehicle Control Units (VCUs), and Battery Management Systems (BMS) right from the early stages of prototyping, reducing the need for extensive physical testing.

The HIL testing solution provides simulated programming that mimics real world conditions and allows various permutations and combinations of test cases and scenarios. Our hardware interface serves as the bridge between real hardware components and the simulated environment, creating a closed-loop system where every action influences the other. Using this technology, our experts help identify potential issues or bugs early in the development process, saving time and reducing the risk of costly errors later in the process.

If you are looking for a reliable solution to streamline your early design and validation process and ensure the optimal performance of your electronic control units, get in touch with us today.

Current Challenges in the Ecosystem

Modern automobiles, especially electric vehicles (EVs) rely heavily on software and connectivity features for functions such as battery management, vehicle diagnostics, and over-the-air updates. There is a significant overhead of validation time and costs and OEMs often find themselves at crossroads between spending on aggressive testing vs improving their product due to following notable challenges:

Time-Consuming Process of Testing and Validation

Higher Setup Costs

Hardware compatibility issues

Restrictions on physical tests due to limited prototypes

Complex simulation models

Unavailability of capabilities to handle large data volumes

HIL simulation becomes an important test solution as it allows engineers to thoroughly validate the performance of hardware and software components in multiple iterations, without the burden of road tests.

How Can HIL Solve the Above Challenges?

Hardware-in-the-Loop (HIL) testing uses the theory of emulation to identify issues in the control units at an early stage. It enhances safety by simulating extreme test cases in controlled environment without risk of damaging expensive prototypes and assembled vehicles. It ensures thorough evaluation of edge cases and failures of software and hardware without having to actually implement it in the vehicle. This This helps improve the quality, and scalability of the final product. Besides this, HIL testing provides the following benefits:

Lowers Innovation Costs and Increases Quality

Encourages Faster Time to Market and a Shorter Testing Duration

Benefits the Environment Due to Optimized R&D

Facilitates Customized and Tailored Solutions for Testing

Features of Our Hardware-in-Loop (HIL) Testing System

Fault injection for robustness evaluation

Emulation of various operating conditions

High-fidelity models for accuracy

Capability to emulate two motors simultaneously

FGPA based simulation of electrical circuit

Application of load variations and faults

Real-time monitoring and data logging

Fault injection for

robustness evaluation

Emulation of various

operating conditions

High-fidelity models

for accuracy

Capability to emulate two

motors simultaneously

FGPA based simulation of

electrical circuit

Application of load

variations and faults

Real-time monitoring and

data logging

HIL Testing Applications

- Test Battery Management Systems (BMS)

- Engine Management System (EMS)

- Electronic Control Units (ECUs)

- Vehicle Control Units (VCUs)

- Motor Control Units (MCUs)

- Advanced Driver Assistance Systems (ADAS)

HIL System Technical Specifications

|

NI 1095 (18 slot chassis) with PXIe 8881 8-core embedded controller

|

-

|

|

PXIe-7820R Digital RIO || FPGA Card DO(0-31) with Mode and Pulse Generation

|

5ns Resolution

|

|

PXIe-7891 FlexRIO Multifunction I/O Module || FPGA Card AO(0-63), AI(0-15), DO(0-31), DI(0-31)

|

20ns Resolution

|

|

PXIe-6363 Multifunction I/O Module || DAQ Card AO(0-3), AI(0-31), DO(0-23),DI(0-23)

|

-

|

|

Pickering Fault Insertion Unit 40-190B-002 || FIU Card (74 Channels)

|

2 nos

|

|

Pickering Resistive 40-295-121-6/24 || Resistive Card 6 Channels (0.25ohms to 16 Mega ohms)

|

3 nos

|

|

PXIe-8510 Vehicle Multiprotocol Interface || CAN Communication Card 6 Channels

|

2 nos

|

|

Capable of upto 750V system voltage

|

-

|

|

Software Interface Wall: LabView, Matlab, NI Veristand

|

-

|

FAQs

HIL simulation is a testing technique where real hardware components are connected to a simulation environment to test their interaction under different operating conditions. It is like setting up a virtual environment where hardware components can be connected and tested as if they were operating in the real world.

HIL testing is commonly used in automotive, aerospace, power systems, and industrial automation industries. It can be applied to systems ranging from automotive engine/ battery control units to aircraft flight control systems.

Prerequisites for HIL testing include a detailed understanding of the system under test, availability of accurate simulation models, suitable hardware-in-the-loop equipment, appropriate interfaces for connecting real and simulated components, and comprehensive test scenarios and requirements. Additionally, robust test automation and data logging capabilities are essential for efficient test execution and analysis.

No. Battery packs and/or motors are not required for testing the electronic control units. All functional tests can be carried out and validated without the actual component in a safe and scientific approach using the HIL equipment.

The price is decided on a project basis after understanding your testing requirements and overall validation objectives. To know more, please get in touch with us at [email protected].

Startups, MSMEs and enterprises can access our HIL Farm Facility at three locations - Bengaluru, Pune and Guwahati. To understand the specifications of HIL equipment available at each location, please contact us at [email protected].