Virtual Abuse Testing for BMS: How Hardware-in-Loop is De-Risking High-Stakes Scenarios Before Road Trials

As electric vehicles (EVs) become mainstream, the reliability of Battery Management Systems (BMS) under extreme conditions is non-negotiable. Engineers at EV component makers face the dual challenge of accelerating innovation while ensuring uncompromised safety.

Virtual abuse testing using an EV HIL Test Bench is transforming how the industry approaches these high-stakes scenarios. This article explores how Hardware-in-Loop testing in automotive applications enable safer, faster, and more cost-effective validation of BMS and related microcontroller units, long before a prototype hits the road.

Common Failure Points in BMS Under Abuse Conditions: Lessons from the Field

Real-world failures have repeatedly shown that BMS vulnerabilities under abuse conditions can result in catastrophic outcomes. Notable industry incidents were traced back to the BMS’s inability to manage overcharging, overheating, and rapid discharge. Key failure points include:

- Inadequate detection of internal short circuits

- Insufficient thermal management leading to runaway events

- Inaccurate State of Charge (SOC) estimation and drift

- Delayed or missed fault responses due to flawed algorithms or sensor failures

Analysis of these failures underscores the importance of designing BMS capable of handling rapid discharge, dissipating heat effectively, and averting overcharge scenarios. Rigorous testing across a wide range of abuse conditions is essential to uncover latent defects before field deployment.

Building Custom Fault Injection Models in HIL: Simulating Internal Short Circuits, Thermal Events & SOC Drift

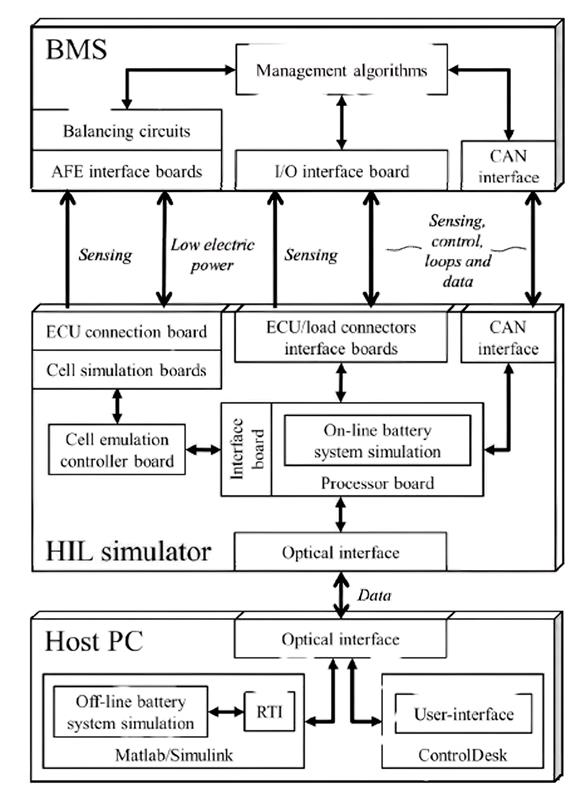

BMS HIL Integration

Source: Research paper by Christian Fleischer, RWTH Aachen University

EV HIL Test Bench technology allows engineers to inject faults and simulate abuse scenarios that are difficult, dangerous, or costly to reproduce with physical hardware. In a recent deployment, a customer’s BMS was subjected to:

- Simulated internal short circuits by manipulating relays and contactors through fault insertion units.

- Emulated thermal runaway events by injecting rapid temperature rise at the sensor interface

- SOC drift scenarios by introducing controlled errors into the SOC calculation modules

The HIL testing of Battery Management Systems enabled the team to validate the BMS logic against these virtualized abuse conditions. The test bench’s real-time simulator orchestrated complex, multi-layered scenarios such as rapid discharge pulses and overvoltage events, while the BMS responded as if connected to a real battery pack. This approach provided:

- Immediate feedback on fault detection and response algorithms

- Safe and repeatable execution of high-risk scenarios with zero risk of fire or hardware damage

- Accelerated test cycles, allowing a year’s worth of aging or abuse to be simulated in hours.

Real Experiences: How HIL Testing De-Risks BMS and Vehicle Control Units

A leading EV startup recently integrated an EV HIL Test Bench into their workflow for both BMS and Vehicle Control Unit (VCU) development. Their engineering team reported:

- Early detection of a latent SOC drift issue that could have led to unexpected shutdowns in the field

- Identification of a thermal event scenario where the BMS failed to trigger secondary protection, now resolved before physical prototyping

- Seamless integration with test automation, enabling overnight regression runs of hundreds of abuse cases.

By leveraging Hardware-in-Loop testing in automotive microcontroller units and VCUs, the startup reduced their physical test lab time by over 40%, cut prototype costs, and eliminated safety incidents during development. The flexibility to automate and iterate on test scenarios allowed them to address design flaws early, reducing the risk of costly recalls or field failures.

Why HIL Testing is Critical for Modern EV Development

Hardware-in-the-Loop (HIL) testing is critical for modern EV development because it enables engineers to validate complex systems—like Battery Management Systems and Vehicle Control Units—under real-time conditions without needing a physical vehicle. By simulating various driving scenarios and fault conditions early in the development cycle, HIL testing helps detect issues faster, reduce development time, lower costs, and ensure safety and performance before road trials.

Feature/Benefit | EV HIL Test Bench | Physical Battery Testing |

Cost | No battery wear, reusable | High cell replacement costs |

Test Speed | Accelerated cycles or manipulated input signals (50Xcycles in an hour) | Limited by battery chemistry |

Risk | Zero thermal runaway risk | Potential fire/explosion |

Fault Injection | Easy, software-driven | Limited, hardware risk |

Scenario Coverage | Comprehensive and repeatable | Limited by safety bounds |

Hardware-in-Loop testing in automotive applications is not just about speed and cost; it is about enabling a culture of safety and innovation. By validating BMS and VCUs in a controlled, virtual environment, engineering teams can confidently launch new products, knowing that the most dangerous scenarios have already been addressed.

| Learn How Power HIL, Digital Twins, and AI/ML Are Shaping the Future of Battery Analysis! |

Book a Live HIL Demo!

Experience the future of BMS and VCU validation. Book a HIL Live demo at the Digital Twin Lab in Jigani, Bangalore, and see firsthand how EV HIL Test Bench solutions are transforming Hardware-in-Loop testing for Battery Management Systems, microcontroller units, and vehicle control units.

Digital Twin Facility is a joint initiative of Micelio and the Automotive Research Association of India (ARAI), focused on creating a powerhouse of digital twin solutions and testing capabilities within the clean mobility industry.

Discover how to de-risk your next EV before it ever leaves the lab. Write to us at [email protected] | +91-9482035699