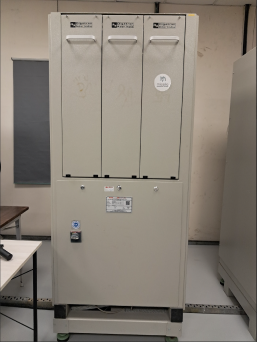

Battery Cycler

Our battery cycler enables engineers and researchers to optimize their battery designs and products to guarantee unmatched reliability. It empowers innovators to fine-tune their battery technologies, ensuring exceptional performance and longevity. Enhance your battery development process with our cycler, delivering precise data to ensure superior reliability and efficiency.

Battery Cyclers are essential equipment for battery pack testing that provide precise evaluation of battery performance, longevity, and efficiency.

Our battery cyclers deliver comprehensive data on capacity, internal resistance, and state-of-health metrics. These devices automate the charging and discharging cycles of individual battery cells or complete battery packs, simulating real-world usage conditions. Also, these are crucial for developing advanced batteries where performance and safety are paramount.

Current Challenges in the Ecosystem

Modern automobiles, especially Electric Vehicles (EVs) rely heavily on software and connectivity features for functions such as battery management, vehicle diagnostics, and over-the-air updates. There is a significant overhead of validation time and costs and OEMs often find themselves at crossroads between spending on aggressive testing vs improving their product due to following notable challenges:

Limited Energy Density

Capacity Degradation

Slow Charging Times

Thermal Runaway

Temperature Sensitivity

Durability and Lifespan

Restricted Range and Usage

Need for Frequent Displacements

Reduced Efficiency

How Can Battery Cyclers Solve the Above Challenges?

Battery Cyclers provide thorough evaluation to help manufacturers optimize battery design, enhancing energy efficiency and driving range. Safety testing under various conditions ensures compliance with stringent industry standards, preventing risks like thermal runaway and battery fires.

Progresses Research and Development for New Battery Types

Simulates Batteries for Extreme Temperatures and Humidity

Encourages Exploration of New Materials

Improves Time to Market by Optimising Battery Characteristics

Features of our Battery Cycler Systems

Battery Testing for Batteries of all Chemistries and Types

Advanced Real-Time Simulation

Comprehensive Data Analysis

Versatility and Scalability

Battery Testing for Batteries

of all Chemistries and Types

Advanced Real-Time

Simulation

Comprehensive

Data Analysis

Versatility and

Scalability

Battery Cycler Testing Applications

Designed to support a wide range of applications, our battery cyclers are highly versatile and scalable. Whether for electric vehicles, renewable energy storage, or consumer electronics, our modular systems can be customized to meet specific testing needs, ensuring flexibility and future-proofing for evolving requirements.

Battery Cycler Systems Specifications

|

Battery Cycler 1 Ador Digatron: 2 Channel |

|

|

Max Voltage

|

120V

|

|

Max Charge/Discharge Current/Per Channel

|

100A

|

|

No. of Channels

|

2

|

|

Max Charge/Discharge Current (Parallel)

|

200A

|

|

Battery Cycler 2 Ador Digatron: 6 Channel |

|

|

Max Voltage

|

120V

|

|

Max Charge/Discharge Current/Per Channel

|

100A

|

|

No. of Channels

|

6

|

|

Max Charge/Discharge Current (Parallel)

|

600A

|

FAQs

Battery testing encompasses all chemistries and types, such as cylindrical, prismatic, and pouch batteries. This testing ensures that batteries meet specific performance, safety, and reliability standards, regardless of their form factor or chemical composition.

No, currently we do not conduct destructive tests in our battery cyclers. Our focus is on non-destructive testing methods that ensure the safety and performance of batteries without compromising their integrity.

Battery Cyclers employ precise control algorithms and advanced monitoring capabilities to ensure the accuracy and reliability of test results. By maintaining tight control over parameters such as temperature, voltage, and current during charging and discharging cycles, Battery Cyclers create a controlled testing environment that closely mimics real-world conditions. Additionally, built-in safety features and fail-safe mechanisms enhance the reliability of testing processes, providing researchers and engineers with confidence in the integrity of their data.

In our lab, we implement several safety measures to prevent thermal runaway of batteries. Continuous temperature monitoring detects abnormal rises, while advanced thermal management systems dissipate heat to maintain safe operating temperatures. Batteries are tested within fire-resistant and explosion-proof enclosures, and automated shut-off systems immediately activate if unsafe temperatures are detected. All staff are trained in safe handling procedures and emergency response.

The price is decided on a project basis after understanding your testing requirements and overall validation objectives. To know more, please get in touch with us at [email protected].